Equipment tools and materials

Equipment: Welding machine, gun welding machine, electric drill tool, handle wire, welding tongs, welding cap, gloves, flat spade steel tape measure spirit level movable handle brush

Material: processing and forming material: forming steel grid plate (in accordance with design requirements) Form: load flat steel 40mm×5mm, load flat steel center spacing 40mm, cross bar center spacing 100mm (planar and toothed) galvanized mounting clips: Galvanized self-tapping screws: zinc-rich paint bits for consumable materials, welding rod screws

Program introduction

Numbering and marking according to layout design drawings; installation guidance according to layout design drawings; load flat steel according to the design meets the material requirements of Q235-A; load test report of steel grid plate; galvanized layer meets specification requirements; flatness of steel grid plate The degree should meet the requirements. Operation sequence Preparation → Check before installation → The steel grid plate is in place in different areas → Temporary fixation → Deviation measurement → Deviation correction → Final fixation

Method of operation

Accurately position and pay off according to the requirements of layout design drawings; place the steel grid plate according to the layout design number into regions and install in regions at the same time. After completing one region, install the next region, each region should be from the middle to both sides Carry out; strictly control the spacing between the steel grid plate and the steel grid plate and other structures according to the specifications during installation; after the steel grid plate is in place, first use the installation clip to temporarily fix it, after the deviation measurement and correction Finally, fix it; the steel grid plate is arranged according to the direction shown in the figure. When it meets the H-shaped steel column, the steel grid plate is opened, and the opening is made of steel plate as 100mm (height)×6mm skirting board. If there is no need to move the steel grid plate after installation, it can be welded to the bracket or steel beam. After welding, the welding slag and flying splash are removed, and two zinc-rich paints are applied manually.

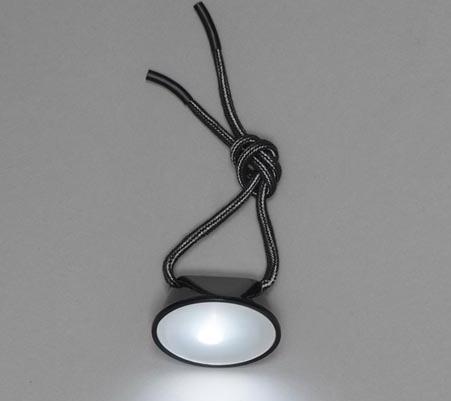

Precautions for grille light installation

- In order to ensure the safe installation, maintenance and inspection of lights, please entrust electrical professionals to take charge. Non-professional construction is prone to danger.

- Do not install the light in the place shown. This luminaire is dedicated to ceiling installation.

- Do not use it in parallel with the dimmer, and do not use it with the dimmer or sensor to avoid malfunctions. Do not install above hot objects or in damp places.

- Light sources larger than a specific maximum power cannot be used (please refer to the power sticker on the product). In any case, the light should not be covered by heat insulation pads or similar materials.

- Make sure there is a 75mm ventilation hole around the product. The use of this light must not violate any fire prevention regulations. Before maintenance, installation and replacement of the light source, please turn off the power and confirm the correct installation of the light source.